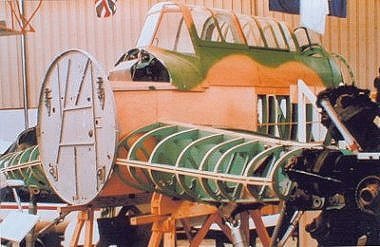

The team are in the process of recreating the forward fuselage panelling rear of the engine installation and also the wing to the fuselage fairings. A couple of weeks ago some members visited the Shuttleworth Trust in Bedfordshire to view their Lysander. The team worked out the shape of the engine cowlings and cooling gills for the engine. The visit was well worthwhile and most informative, so the Museum now has some good photographs for the next task.

The forward cowling manufacture is progressing. The left hand side is now complete and the right hand side is being manufactured.

We are currently looking into the possibility of obtaining engine cowlings, gill assembly and exhaust collector for the Martinet, unserviceable items of course, there must be some tucked away somewhere. "The boys" have made a start on the tinware fwd of the cockpit up to the gill assy, which is fairly straight forward.

The flaps have proven awkward but all problems are now resolved on this part. Covering the wings is going well but the part you still see open on top is required while we completing the aileron controls, all under surface is now skinned..

Since October quite a bit has been achieved on the Martinet. The centre section is now ply covered completly on the underside and the top surface is just awaiting us finishing the flap installation. This has proven more dificult than expected. We made up one set of hinges and thought they worked, but because we had made the hinge centre to close to the wing, it fouled the structure as it was lowered. Back to the drawing board. After drawing it out, we seem to have it right now and once they are on the centre section, the skinning can be finished. Work is also being carried out inside of the cockpit on the aileron controls.

The first picture shows the wing skinning coming along. The second picture shows the port flap complete. We are making the hinges to mount this to the centre section. Just done a dummy run this afternoon and it fits fine. This has been an awkward shape to deal with, but we are pleased with the results

The Martinet is on its only legs for the first time since July 1951.

The first picture shows the tailplane structure we are working on in the workshop, the other is the ply covering to the top of the fuselage which is being formed to shape over the fuselage.

With the port side covered with ply, we are now working on the flying controls before closing the other side. Though it doesn't show up on this picture, the tail wheel strut is now on.

The Martinet is on it undercarriage now!

The selection of photographs below show our progress to date.

The restoration carries on albeit slowly. The main constraint on the rate of progress is due to the team members inability to spend as much time as they would like on the project.

The canopy has been completely stripped down to component level ready to be completely cleaned and stripped of all paint and corrosion before the task of re-building is started. Some component parts will have to be re-manufactured as they are so far gone as to be unusable.

This section is now nearly stripped to component level and the first task will be to evaluate the amount of rebuilding work that is required. Many of the undercarriage mounting components are being bead blasted to find out the true nature of the corrosion etc. Patterns of the leading edge have been manufactured to enable the definition to be found. Then the task of building up the leading edge can start. The two members of the team who are concentrating on this part of the restoration are busy manufacturing panels and formers etc. and the rest of us hope to see something to hang our bits on!

We now have all but one of the instruments required to complete the panel. All that is now needed is a few switches etc., and the panel will be complete. As you can see from the image we were lucky to have found so much material so quickly.

On April 26th 1997 we took delivery of some parts of a Miles Master that were brought down from Yorkshire. It was like an Alladins Cave! The remaining instruments required were found, much to the relief of all. Many other pieces, which at first glance might be called rubbish, delighted all the team involved! As the instrument panel will be as complete as possible for now, we shall now try to concentrate on the aircraft's seat. The seat is nearly built, as is the control column, which has been marvelously restored by one of the team. I hope to have an image of this soon.